High speed motors are receiving increasing attention due to their obvious advantages such as high power density, small size and weight, and high work efficiency. An efficient and stable drive system is the key to fully utilizing the excellent performance of high-speed motors. This article mainly analyzes the difficulties of high-speed motor drive technology from the aspects of control strategy, corner estimation, and power topology design, and summarizes the current research results at home and abroad. Afterwards, it summarizes and prospects the development trend of high-speed motor drive technology.

Part 02 Research Content

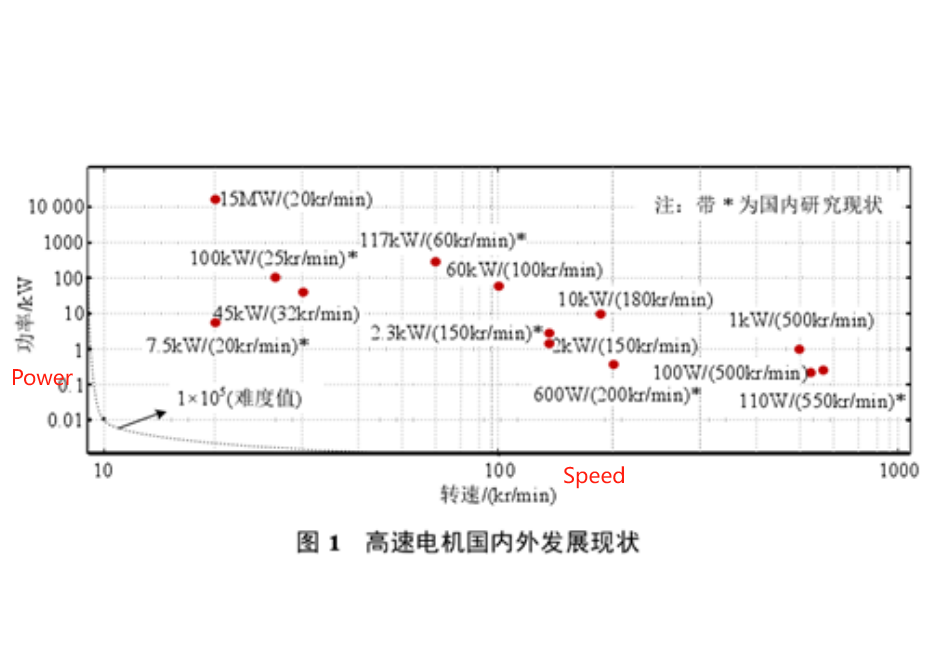

High speed motors have many advantages such as high power density, small volume and weight, and high work efficiency. They are widely used in fields such as aerospace, national defense and safety, production and daily life, and are necessary research content and development direction today. In high-speed load applications such as electric spindles, turbomachinery, micro gas turbines, and flywheel energy storage, the application of high-speed motors can achieve a direct drive structure, eliminate variable speed devices, significantly reduce volume, weight, and maintenance costs, while significantly improving reliability, and has extremely broad application prospects. High speed motors usually refer to speeds exceeding 10kr/min or difficulty values (product of speed and square root of power) exceeding 1 × The motor of 105 is shown in Figure 1, which compares the relevant data of some representative prototypes of high-speed motors both domestically and internationally. The dashed line in Figure 1 is 1 × 105 difficulty level, etc

1、 Difficulties in High Speed Motor Drive Technology

1. System stability issues at high fundamental frequencies

When the motor is in a high operating fundamental frequency state, due to limitations such as analog-to-digital conversion time, digital controller algorithm execution time, and inverter switching frequency, the carrier frequency of the high-speed motor drive system is relatively low, resulting in a significant decrease in motor operating performance.

2. The problem of high-precision rotor position estimation in fundamental frequency

During high-speed operation, the accuracy of rotor position is crucial for the operational performance of the motor. Due to the low reliability, large size, and high cost of mechanical position sensors, sensorless algorithms are often used in high-speed motor control systems. However, under high operating fundamental frequency conditions, the use of position sensorless algorithms is susceptible to non ideal factors such as inverter nonlinearity, spatial harmonics, loop filters, and inductance parameter deviations, resulting in significant rotor position estimation errors.

3. Ripple suppression in high-speed motor drive systems

The small inductance of high-speed motors inevitably leads to the problem of large current ripple. The additional copper loss, iron loss, torque ripple, and vibration noise caused by high current ripple can greatly increase the losses of high-speed motor systems, reduce motor performance, and the electromagnetic interference caused by high vibration noise can accelerate the aging of the driver. The above issues greatly affect the performance of high-speed motor drive systems, and the optimization design of low loss hardware circuits is crucial for high-speed motor drive systems. In summary, the design of a high-speed motor drive system requires comprehensive consideration of multiple factors, including current loop coupling, system delay, parameter errors, and technical difficulties such as current ripple suppression. It is a highly complex process that places high demands on control strategies, rotor position estimation accuracy, and power topology design.

2、 Control Strategy for High Speed Motor Drive System

1. Modeling of High Speed Motor Control System

The characteristics of high operating fundamental frequency and low carrier frequency ratio in high-speed motor drive systems, as well as the influence of motor coupling and delay on the system, cannot be ignored. Therefore, considering the above two major factors, modeling and analyzing the reconstruction of high-speed motor drive systems is the key to further improving the driving performance of high-speed motors.

2. Decoupling Control Technology for High Speed Motors

The most widely used technology in high-performance motor drive systems is FOC control. In response to the serious coupling problem caused by high operating fundamental frequency, the main research direction currently is decoupling control strategies. The decoupling control strategies currently studied can be mainly divided into model based decoupling control strategies, disturbance compensation based decoupling control strategies, and complex vector regulator based decoupling control strategies. Model based decoupling control strategies mainly include feedforward decoupling and feedback decoupling, but this strategy is sensitive to motor parameters and can even lead to system instability in cases of large parameter errors, and cannot achieve complete decoupling. The poor dynamic decoupling performance limits its application range. The latter two decoupling control strategies are currently research hotspots.

3. Delay Compensation Technology for High Speed Motor Systems

Decoupling control technology can effectively solve the coupling problem of high-speed motor drive systems, but the delay link introduced by delay still exists, so effective active compensation for system delay is needed. At present, there are two main active compensation strategies for system delay: model based compensation strategies and model independent compensation strategies.

Part 03 Research Conclusion

Based on the current research achievements in high-speed motor drive technology in the academic community, combined with existing problems, the development and research directions of high-speed motors mainly include: 1) research on precise prediction of high fundamental frequency current and active compensation delay related issues; 3) Research on high dynamic performance control algorithms for high-speed motors; 4) Research on precise estimation of corner position and full speed domain rotor position estimation model for ultra high speed motors; 5) Research on full compensation technology for errors in high-speed motor position estimation models; 6) Research on High Frequency and High Loss of High Speed Motor Power Topology.

Post time: Oct-24-2023