The motor shaft is hollow, with good heat dissipation performance and can promote lightweight of the motor. Previously, motor shafts were mostly solid, but due to the use of motor shafts, the stress was often concentrated on the surface of the shaft, and the stress on the core was relatively small. According to the bending and torsional properties of material mechanics, the internal part of the motor shaft was appropriately hollowed out, and only a small outer diameter was needed to increase the external part. The hollow shaft can meet the same performance and function as the solid shaft, but its weight can be significantly reduced. Meanwhile, due to the hollowing of the motor shaft, cooling oil can enter the interior of the motor shaft, increasing the heat dissipation area and improving the heat dissipation efficiency. Under the current trend of 800V high-voltage fast charging, the advantage of hollow motor shafts is greater. The current production methods for hollow motor shafts mainly include solid shaft hollowing, welding, and integrated forming, among which welding and integrated forming are widely used in production.

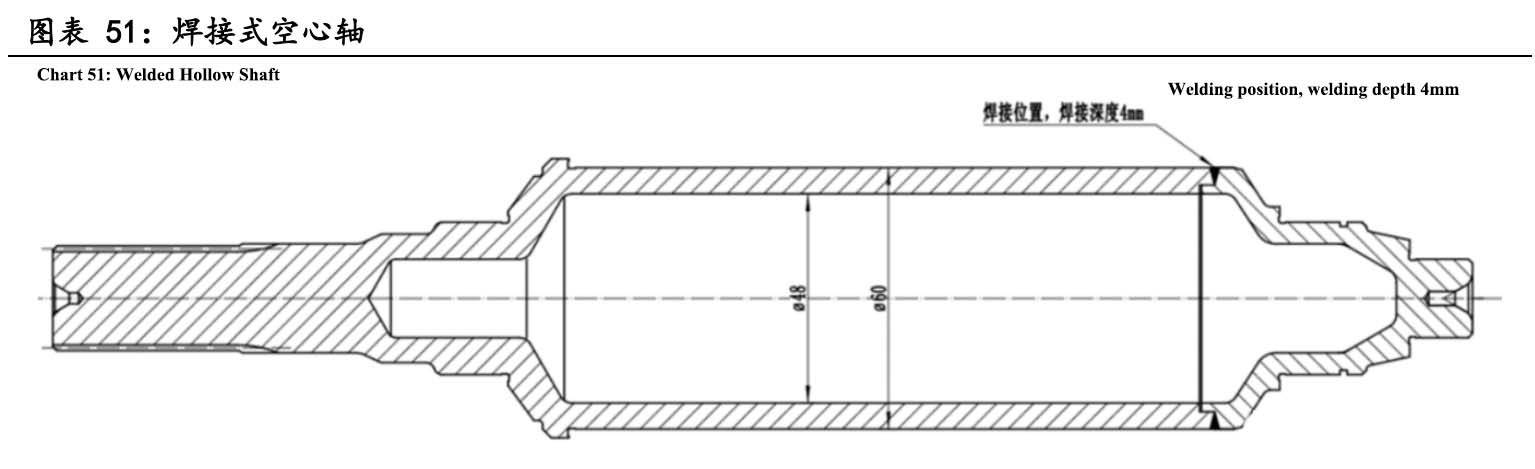

The welded hollow shaft is mainly achieved through extrusion forming to achieve a stepped inner hole of the shaft, and then machined and welded into shape. By extrusion molding, the shape changes of the inner hole with the product structure and strength requirements are retained as much as possible. Generally, the basic wall thickness of the product can be designed below 5mm. Welding equipment generally adopts butt friction welding or laser welding. If butt friction welding is used, the position of the butt joint is generally about 3mm welding protrusion. Using laser welding, the welding depth is generally between 3.5 and 4.5mm, and the welding strength can be guaranteed to be greater than 80% of the substrate. Some suppliers can even achieve over 90% of the substrate strength through strict process control measures. After the welding of the hollow shaft is completed, it is necessary to conduct ultrasonic or X-ray testing on the microstructure and weld quality of the welding area to ensure product consistency.

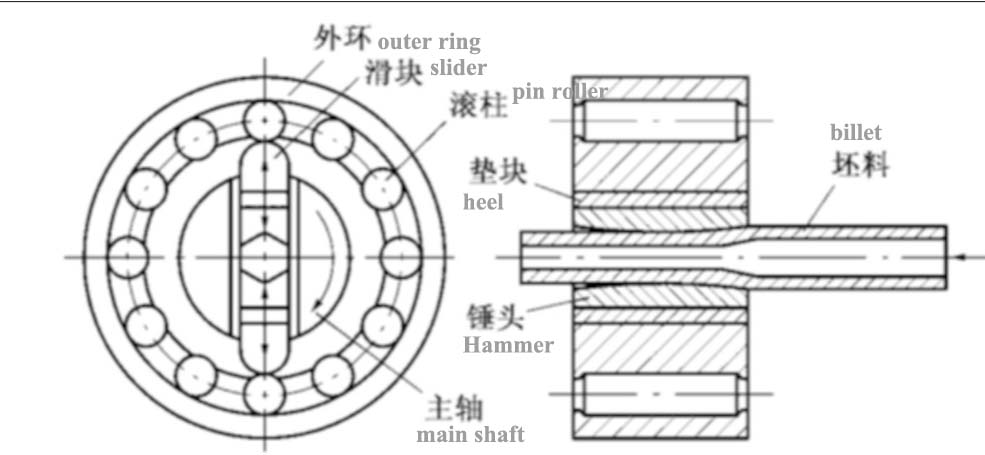

The integrated forming hollow shaft is mainly forged by external equipment on the blank, enabling the internal part to directly achieve a stepped inner hole of the shaft. At present, radial forging and rotary forging are mainly used, and the equipment is mainly imported. The radial forging is typical of FELLS company’s equipment, while the rotary forging is typical of GFM company’s equipment. Radial forging forming is generally achieved by using four or more symmetrical hammers at a frequency of over 240 blows per minute to achieve small deformation of the blank and direct hollow tube blank forming. Rotary forging forming is the process of evenly arranging multiple hammer heads in the circumferential direction of the billet. The hammer head rotates around the axis while performing radial high-frequency forging on the workpiece, reducing the cross-sectional size of the billet and extending axially to obtain the workpiece. Compared to traditional solid shafts, the manufacturing cost of integrated formed hollow shafts will increase by about 20%, but the weight of motor shafts will generally be reduced by 30-35%.

Post time: Sep-15-2023