1.What are the commonly used cooling technologies for electric vehicle motors?

Electric vehicles (EVs) use various cooling solutions to manage the heat generated by the motors. These solutions include:

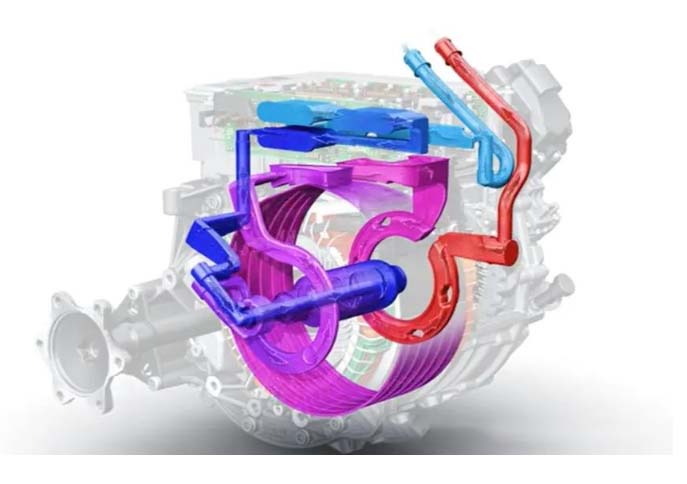

Liquid Cooling: Circulate a coolant fluid through channels inside the motor and other components. Helps maintain optimal operating temperatures, resulting in higher dissipation heat efficiency compared to air cooling.

Air Cooling: Air is circulated over the motor’s surfaces to dissipate heat. Although air cooling is simpler and lighter, its effectiveness may not be as good as liquid cooling, especially in high-performance or heavy-duty applications.

Oil Cooling: The oil absorbs heat from the motor and then circulates through the cooling system.

Direct Cooling: Direct cooling refers to the use of coolants or refrigerants to directly cool the stator windings and rotor core, effectively controlling heat in high-performance applications.

Phase change materials (PCM): These materials absorb and release heat during phase transitions, providing passive thermal management. They help regulate temperature and reduce the need for active cooling methods.

Heat exchangers: Heat exchangers can transfer heat between different fluid systems, such as transferring heat from engine coolant to the cabin heater or battery cooling system.

The choice of cooling solution depends on factors such as the design, performance requirements, thermal management needs, and intended use of electric vehicles. Many electric vehicles integrate these cooling methods to optimize efficiency and ensure the longevity of the motor.

2.What are the most advanced cooling solutions?

Two Phase Cooling Systems: These systems use phase change materials (PCM) to absorb and release heat when transitioning from liquid to gas. This can provide efficient and compact cooling solutions for electric vehicle components, including motors and power electronic devices.

Microchannel Cooling: Microchannel cooling refers to the use of tiny channels in a cooling system to enhance heat transfer. This technology can improve heat dissipation efficiency, reduce the size and weight of cooling components.

Direct Liquid Cooling: Direct liquid cooling refers to the direct circulation of coolant in a motor or other heat generating component. This method can provide precise temperature control and efficient heat removal, which helps to improve the performance of the entire system.

Thermoelectric Cooling: Thermoelectric materials can convert temperature differences into voltage, providing a pathway for localized cooling in specific areas of electric vehicles. This technology has the potential to address target hotspots and optimize cooling efficiency.

Heat Pipes: Heat pipes are passive heat transfer devices that utilize the phase change principle for efficient heat transfer. It can be integrated into electric vehicle components to improve cooling performance.

Active Thermal Management: Advanced control algorithms and sensors are used to dynamically adjust cooling systems based on real-time temperature data. This ensures optimal cooling performance while minimizing energy consumption.

Variable Speed Cooling Pumps: Tesla’s cooling system may use variable speed pumps to adjust coolant flow rates according to temperature requirements, thereby optimizing cooling efficiency and reducing energy consumption.

Hybrid Cooling Systems: Combining multiple cooling methods, such as liquid cooling and phase change cooling or microchannel cooling, can provide a comprehensive solution for optimizing heat dissipation and thermal management.

It should be noted that to obtain the latest information on the latest cooling technologies for electric vehicles, it is recommended to consult industry publications, research papers, and electric vehicle manufacturers.

3. What challenges do advanced motor cooling solutions face?

Complexity and Cost: The use of advanced cooling systems such as liquid cooling, phase change materials, or microchannel cooling will increase the complexity of electric vehicle design and manufacturing processes. This complexity will lead to higher production and maintenance costs.

Integration and Packaging: Integrating advanced cooling systems into the narrow space of electric vehicle structures is challenging. Ensuring appropriate space for cooling components and managing fluid circulation paths may be very difficult without affecting the vehicle structure or space.

Maintenance and Repairs: Advanced cooling systems may require specialized maintenance and repairs, which may be more complex than traditional cooling solutions. This may increase the maintenance and repair costs for electric vehicle owners.

Efficiency and Energy Consumption: Some advanced cooling methods, such as liquid cooling, may require additional energy for pump operation and liquid circulation. Finding a balance between improving cooling efficiency and potentially increasing energy consumption is a challenge.

Material Compatibility: When selecting materials for advanced cooling systems, careful consideration must be given to ensure compatibility with coolants, lubricants, and other fluids. Incompatibility may cause corrosion, leakage, or other issues.

Manufacturing and Supply Chain: The adoption of new cooling technologies may require changes in manufacturing processes and supply chain procurement, which may result in production delays or challenges.

Reliability and Longevity: Ensuring the long-term reliability and durability of advanced cooling solutions is crucial. Malfunctions in the cooling system can lead to overheating, performance degradation, and even damage to critical components.

Environmental Impact: The production and disposal of advanced cooling system components (such as phase change materials or specialized fluids) may have an impact on the environment and need to be considered.

Despite these challenges, related research and development work is being vigorously promoted, and in the future, these advanced cooling solutions will be more practical, efficient, and reliable. With the advancement of technology and the accumulation of experience, these challenges will gradually be alleviated.

4.What factors need to be considered in the design of motor cooling system?

Heat Generation: Understand the heat generation of the motor under different operating conditions. This includes factors such as power output, load, speed, and operating time.

Cooling Method: Choose an appropriate cooling method, such as liquid cooling, air cooling, phase change materials, or combination cooling. Consider the advantages and disadvantages of each method based on the heat dissipation requirements and available space of the motor.

Thermal Management Zones: Identify specific areas within the motor that require cooling, such as stator windings, rotor, bearings, and other critical components. Different parts of the motor may require different cooling strategies.

Heat Transfer Surface: Design effective heat transfer surfaces, such as fins, channels, or heat pipes, to ensure effective heat dissipation from the motor to the cooling medium.

Cooling Selection: Select an appropriate coolant or thermal conductive liquid to provide efficient heat absorption, transfer, and release. Consider factors such as thermal conductivity, compatibility with materials, and impact on the environment.

Flow Rate and Circulation: Determine the required coolant flow rate and circulation mode to fully remove engine heat and maintain a stable temperature.

Pump and Fan Sizing: Reasonably determine the size of the cooling pump and fan to ensure sufficient coolant flow and airflow for effective cooling, while avoiding excessive energy consumption.

Temperature Control: Implement a control system to monitor the motor temperature in real-time and adjust cooling parameters accordingly. This may require the use of temperature sensors, controllers, and actuators.

Integration with Other Systems: Ensure compatibility and integration with other vehicle systems, such as battery thermal management systems and power electronic cooling systems, to create a holistic thermal management strategy.

Materials and Corrosion Protection: Select materials that are compatible with the selected coolant and ensure appropriate anti-corrosion measures are taken to prevent degradation over time.

Space Constraints: Consider the available space inside the vehicle and the design of the engine to ensure effective integration of the cooling system without affecting other components or vehicle design.

Reliability and Redundancy: When designing a cooling system, reliability should be considered and redundant or backup cooling methods should be used to ensure safe operation in the event of component failure.

Testing and Validation: Conduct comprehensive testing and validation to ensure that the cooling system meets performance requirements and can effectively control temperature under various driving conditions.

Future Scalability: Consider the potential impact of future motor upgrades or vehicle design changes on the effectiveness of the cooling system.

The design of motor cooling systems involves interdisciplinary methods, combining engineering expertise in thermal dynamics, fluid mechanics, materials science, and electronics.

Post time: Mar-06-2024