The vibration of permanent magnet synchronous motors mainly comes from three aspects: aerodynamic noise, mechanical vibration, and electromagnetic vibration. Aerodynamic noise is caused by rapid changes in air pressure inside the motor and friction between the gas and the motor structure. Mechanical vibration is caused by periodic elastic deformation of bearings, geometric defects, and rotor shaft imbalance. Electromagnetic vibration is caused by electromagnetic excitation, and the air gap magnetic field acts on the stator core, causing radial deformation of the stator, which is transmitted to the motor casing and radiates noise. Although the tangential component of the air gap magnetic field is small, it can cause cogging torque ripple and motor vibration. In the propulsion of permanent magnet synchronous motors, electromagnetic excitation is the main source of vibration.

In the initial design stage of permanent magnet synchronous motors, by establishing a vibration response model, analyzing the properties of electromagnetic excitation and the dynamic characteristics of the structure, predicting and evaluating the level of vibration noise, and optimizing the design for vibration, vibration noise can be reduced, motor performance can be improved, and the development cycle can be shortened.

The current research progress can be summarized into three aspects:

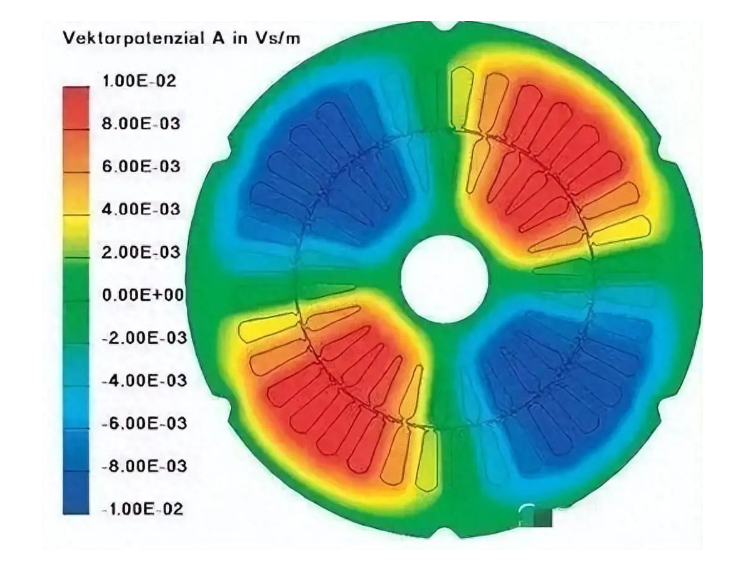

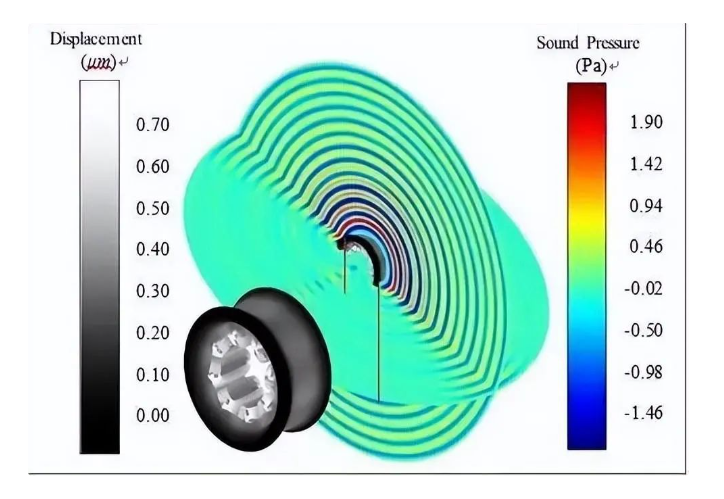

1.Research on electromagnetic excitation: Electromagnetic excitation is the fundamental cause of vibration, and research has been ongoing for many years. Early research included calculating the distribution of electromagnetic forces inside motors and deriving analytical formulas for radial forces. In recent years, finite element simulation methods and numerical analysis have been widely applied, and domestic and foreign scholars have studied the influence of different pole slot configurations on the cogging torque of permanent magnet synchronous motors.

2. Research on structural modal characteristics: The modal characteristics of a structure are closely related to its vibration response, especially when the excitation frequency is close to the natural frequency of the structure, resonance will occur. Domestic and foreign scholars have studied the structural characteristics of motor stator systems through experiments and simulations, including factors that affect modal frequencies such as materials, elastic modulus, and structural parameters.

3. Research on Vibration Response under Electromagnetic Excitation: The vibration response of a motor is caused by the electromagnetic excitation acting on the stator teeth. Researchers analyzed the spatiotemporal distribution of electromagnetic force, loaded electromagnetic excitation onto the motor stator structure, and obtained numerical calculations and experimental results of the vibration response. The researchers also investigated the influence of the damping coefficient of the shell material on the vibration response.

Post time: Mar-06-2024